Additive manufacturing

Limits of machining processes

Powder bed method SLM

Additive manufacturing by NONNENMANN

FREQUENTLY ASKED QUESTIONS

The FAQ’s for additive manufacturing

Which advantages does NONNENMANN offer?

We offer you the complete package so that you receive the final ready-to-install component from us. According to your design data, we take over the additive manufacturing (SLM process with tool steel) and the necessary subsequent finishing as an extended workbench. You benefit from the advantages of additive manufacturing without having to invest in expensive machine technology yourself, which would not be fully utilized in conventional toolmaking anyway.

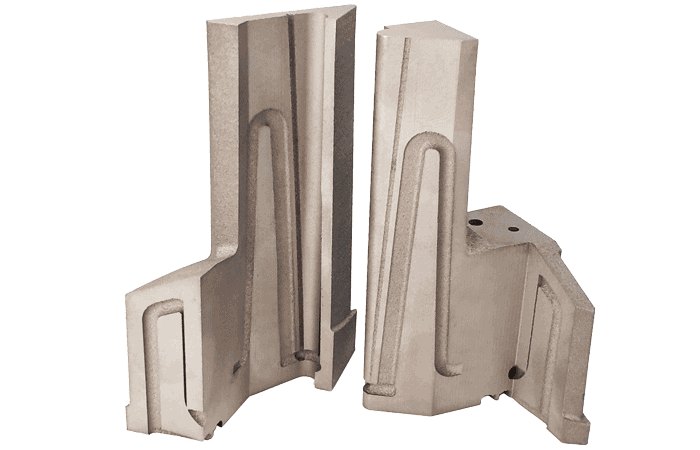

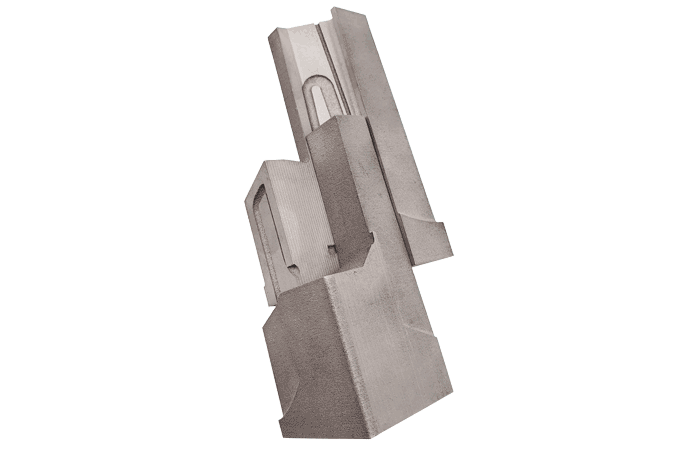

What are the advantages of near-contour temperature control?

In plastics processing, mold temperature control has a major influence on the component quality of the injection molded part as well as the entire manufacturing process, and determines efficient and economical production. The basic goal of temperature control must therefore be a uniform mold wall temperature. This goal can be achieved by the use of conformal temperature control, as local temperature increases are avoided. The temperature control channels follow the cavity contour. Even small channel cross-sections close to the surface can be realized. This freedom of flexible arrangement of the temperature control channels is made possible by additive manufacturing. This results in the advantages of higher cooling capacities, better part quality and shorter cycle times, which reduces the reject rate and increases the output per mold and machine.

Which tool steels for additive manufacturing are possible?

Currently, only a few materials are available for this purpose, since not every material known from conventional production is also available or realizable in powder form. The future focus is therefore on further material development.

Currently, we offer you a choice of two materials (tool steels):

-

- 1.2709: established for 3D printing and, thanks to its technical properties, suitable for many applications and requirements in tool and die making

- similar to 1.2083: our novelty, a corrosion-resistant tool steel already known from conventional production. This material has very similar properties to 1.2083, but slightly different in composition, as the powder had to be optimized and adapted for 3D printing.

.

What must be taken into account in the design?

The potentials of additive manufacturing must be considered already in the design phase. This requires a rethinking in the design phase. Here, the designers are called upon to design the component for additive manufacturing. For example, support structures are required for slopes greater than 45° or drill holes greater than 8mm and must be designed in. The maximum dimension for additive manufacturing is 250x250x300mm. The minimum bore diameter is Ø1mm. Wall thicknesses must be at least 1mm. It should be noted that not everything that has been classically manufactured and machined is now suitable for 3D printing. The technology must be used in a targeted manner in order to benefit from the advantages of the additive-manufactured component in the subsequent production process.

CONTACT US NOW

Benefit from the advantages of additively manufactured components