PropNew

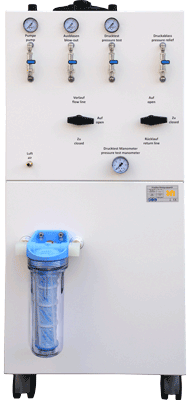

Cleaning device

PropNew is a mobile multi-purpose cleaning device for ensuring optimum efficiency of temperature control systems.

Suitable for

- Injection molds

- Complete injection molding machines including tools

- Temperature control units

- Plate heat exchanger

Optionally with

- Measurement for flow rate and PH-value

- Conservation tank

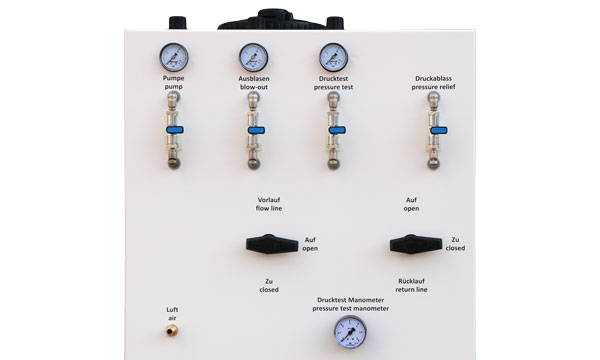

INTUITIVE AND MULTIFUNCTIONAL

PropNew is suitable for all temperature control channels and offers optimum cleaning and analysis functions.

The following programs are started using the easy-to-use console:

(e.g., before storage)

EFFICIENT AND EFFECTIVE

PropNew cleans your systems independently of lime, rust and other deposits without time-consuming disassembly.

The reduction of the oil temperature in injection molding machines by 15 ° C is a realistic goal for inadequately maintained systems. As a result, trouble-free production is ensured and machine failures are avoided.

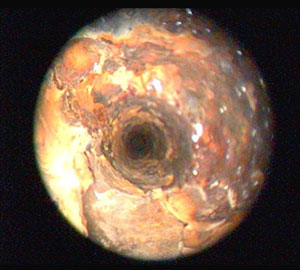

- Before cleaning

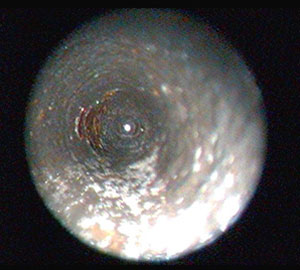

- After cleaning with PropNew

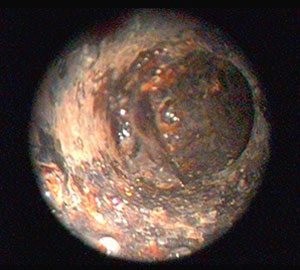

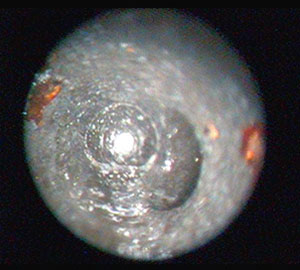

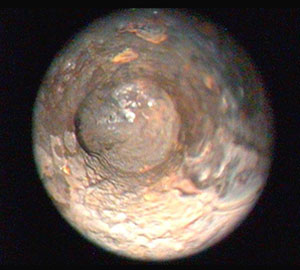

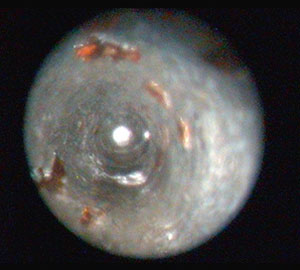

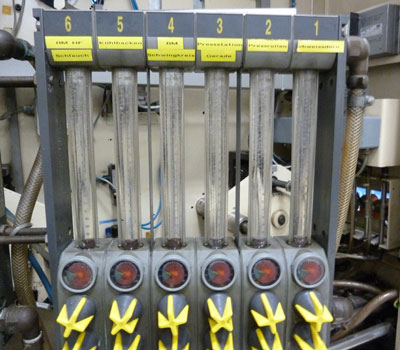

VISIBLY SUCCESSFUL

In the temperature control channels of the injection molds and in the flow meter, PropNew will remove deposits thoroughly.

Channel 1

Channel 2

Channel 3

Before cleaning

After cleaning

PROVEN TECHNOLOGY

PropNew was designed to make the cleaning process easier and more effective.

Internal hose reel

Dimensions (B x L x H)

530 x 790 x 1200 mm

Tank capacity

100 liters

Weight

67 kg

Pump

Max. Flow rate: 10 l/min

Max. Delivery pressure: 6 bar

with CE-Labeling

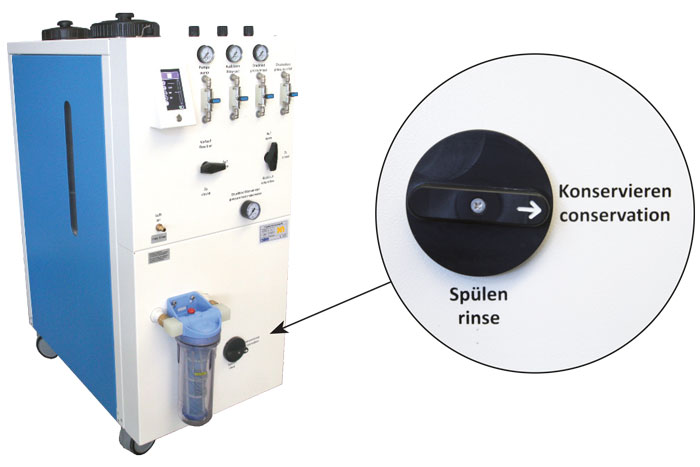

DEVICE OPTIONS AVAILABLE

Option 1: Measurement of flow rate and PH value

Option 2: Tank for conservation

Measurement of flow rate and PH-value

Conservation tank

ACCESSORIES AND CONCENTRATES

Matched to PropNew cleaning devices

FREQUENTLY ASKED QUESTIONS

The FAQ’s for PropNew

For which applications can the PropNew cleaning device be used?

Cleaning, preservation, testing of temperature control channels and heat exchangers of all kinds.

Can the flow rate also be checked with the device?

Yes, if PropNew is ordered with the instrument option “Flow and PH measurement”.

How does cleaning work?

The device is connected to the temperature control channel via temperature couplings. Switch on flushing, flush for approx. 2h, then blow the cleaning solution back into the tank.

Can a temperature control channel be tested for tightness?

Yes, the “pressure test” function already built into the standard version is used to apply compressed air to the temperature control duct and test for leaks.

Do the cleaners used attack metals?

Yes, therefore contact with polished surfaces and cavities should be avoided. Temperature control channels are not damaged.

Care should only be taken with tempering channels that are coated with electroless nickel!

Which connections are necessary for operation?

Only compressed air. Additionally for the option “Measurement flow rate and PH-value” 220V to charge the battery of the display.

Why is there an option for a second tank?

The second tank contains the preservative. You can switch over to the second tank in one easy step.

You can buy PropNew or rent on a weekly basis.

Ask for your offer for the multifunctional cleaning unit PropNew today.

The corresponding chemicals are, of course, supplied as accessories.

CONTACT US NOW

Ensure the optimum efficiency of your temperature control systems.

Jochen Schwegler

Consultant Plastic Injection Molding/Mold Making/Project Planning

+49(0)7181/4087-217

+49(0)7181/45351

+49(0)152/09 01 11 63

j.schwegler@nonnenmann.net