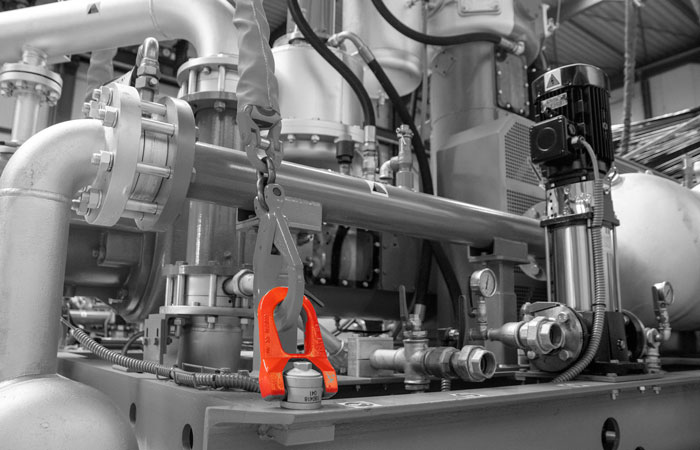

Swivel lifting rings

High occupational safety

DSR

DSS

Mega.DSS

Giga.DSS

SEB

TSR

DSH

DSP

FE.DSR | FE.DSS | FE.SEB

SS.DSR | SS.FE.DSR | SS.DSS | SS.FE.DSS | SS.SEB

QL.DSR

Other variants and optional accessories

FREQUENTLY ASKED QUESTIONS

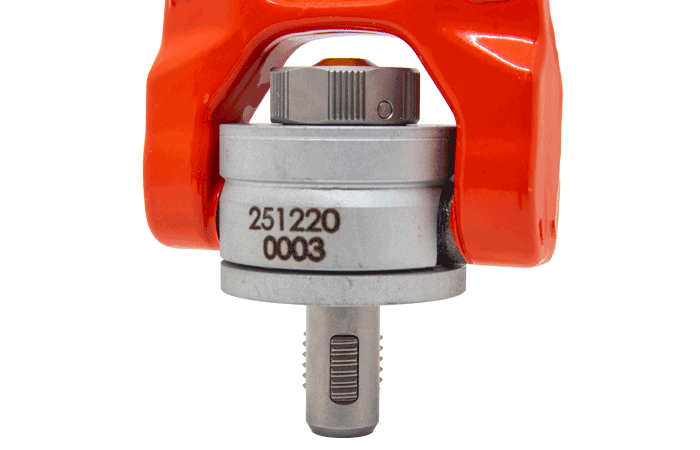

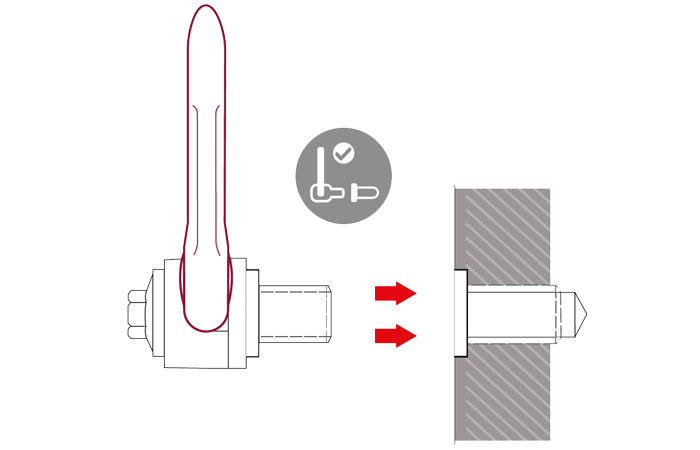

How is the QLR function operated?

The purely mechanical system is equipped with a bolt instead of a continuous thread, on which there is a threaded insert with three thread segments at the lower end for locking. By pressing the pushbutton, the threaded insert is retracted and the lifting device can be inserted into the threaded hole of the component. When the pushbutton is released, the thread segments fit snugly into the respective internal thread. Pressing again unlocks the system for disassembly. Actuation is only possible in the no-load condition, thus accidental loosening under load is impossible.

What is the load capacity from the QLR to the standard double swivel ring screw?

The payloads of the QLR models are about 40% lower compared to the Double swivel ring screwn with full thread Ø. Please refer to the data sheet on the website for the respective load capacities. QLR is designed for applications where the focus is on the time advantage From to 80% and is recommended for frequent changes during the day.

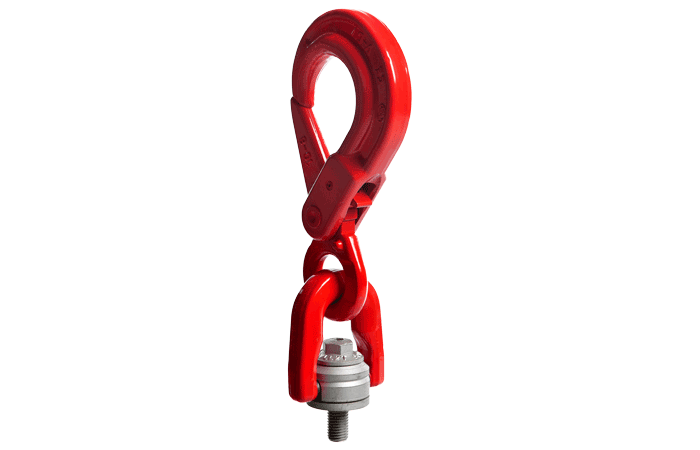

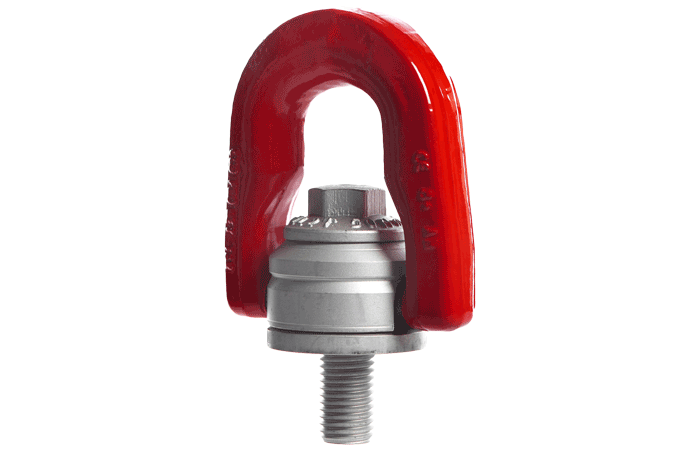

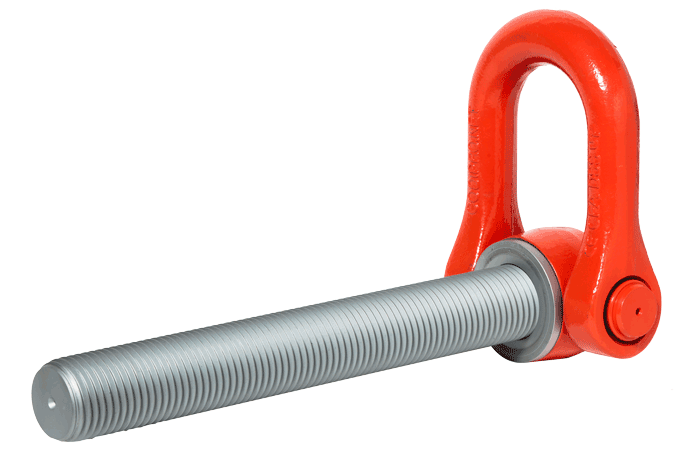

How are Double swivel ring screwn constructed and what are the advantages?

The lifting devices can be loaded in all directions, making them suitable for lifting operations in straight, inclined and 90° pulling directions, as well as for any rotary movements under load. The centered attachment points consist of a double joint and a shackle. This design always guarantees ideal alignment in the direction of pull and allows components to rotate 360° and swivel 180° even under load. This ensures full safety during any lifting operation and there is no risk of the components unscrewing on their own.

What is the difference between double swivel ring screwn and eyebolts according to DIN580?

Fixed eyebolts according to DIN580 are only approved for straight pull directions, lifting operations with 90° pull are prohibited. In addition, these lifting devices are rigid and do not align themselves in the load direction during lifting. This may cause the eyebolt to loosen by itself.

How is the safety of the lifting equipment ensured?

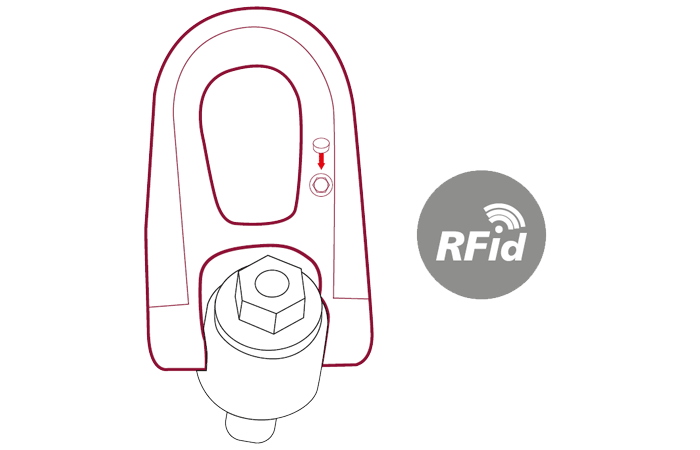

In addition to meeting the basic safety requirements, additional regular strict controls are carried out. In addition, an individual code is engraved in each product for clear traceability. To ensure the safety of the products, various tests for resistance and quality are carried out during production, including tensile strength test, load test with WLLx2.5 in 90° tensile direction, load change test and 100% crack test.

Contact us now