AUTOMATION

Optimize your production processes by using cost- and time-saving peripherals for injection molding.

Consultation with you on site

Analysis of the processes

Optimization of your processes

THE POTENTIAL

Automation frees up resources and thus increases your competitiveness.

THE CHALLENGE

Personnel-related machine setups prevent efficient production in many spray shops

Machine loading

Removal of the manufactured product from the machine

Onward transport of manufactured products

Sorting and palletizing of components

Workpiece inspection (testing, inspecting, measuring)

THE VIEW FROM THE OUTSIDE

We continuously advise customers on how to optimize their processes.

You too can benefit from a targeted review of current processes and the identification of optimization potential in production sequences, the use of cost- and time-saving peripherals for injection molding.

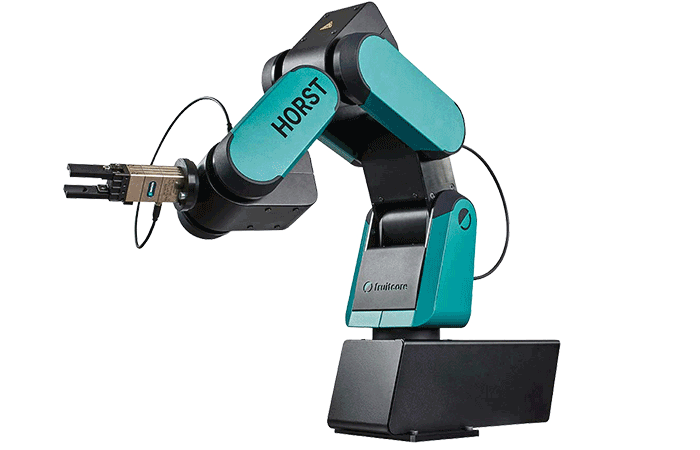

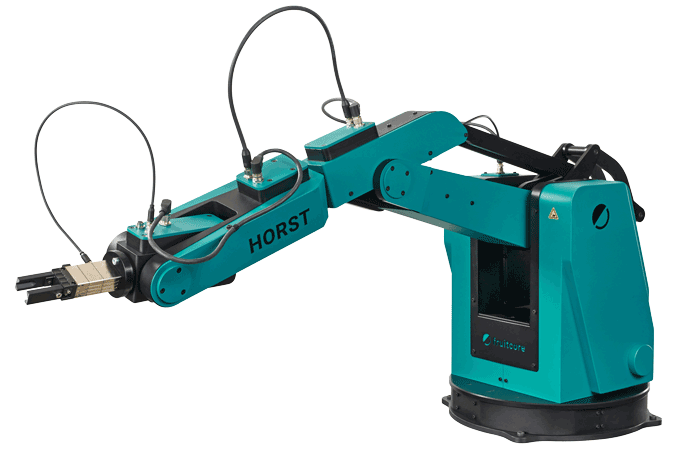

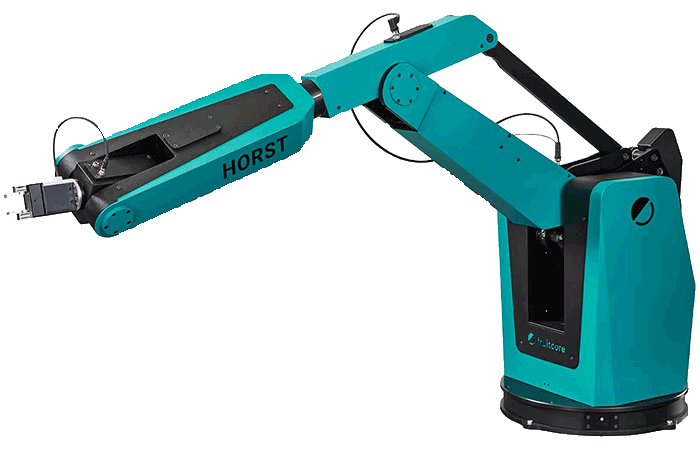

Solutions for small applications (low range and low nominal loads) to applications with high payloads and ranges.

ROBOT VARIANTS

For different ranges and nominal loads.

Contact now us now

You too can benefit from the advantages of our automation solutions

We will be happy to advise you on the automation of your production:

+49(0)7181-4087-0

For more information about the industrial robots, visit the manufacturer's site: fruitcore robotics.