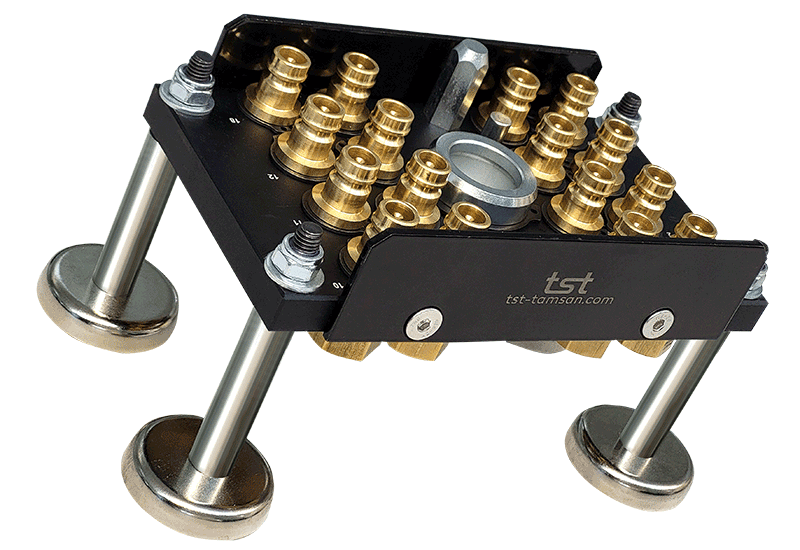

MAGNETIC HOLDER FOR MULTI COUPLINGS

Mounting the multi-coupling with the aid of four magnets, as an alternative to the classic screw connection on the mold, enables flexible positioning as no threaded holes are required on the mold.

MAGNETIC HOLDER FOR MULTI COUPLINGS

Mounting the multi-coupling with the aid of four magnets, as an alternative to the classic screw connection on the mold, enables flexible positioning as no threaded holes are required on the mold.

The magnetic holder can be used for the multi-coupling series M009, M090, M109, M152 and M155. Standard mounting accessories for the multi-couplings are still used for mounting and are supplemented by the magnetic holders.

Automation as an all-in-one solution

Our automation solution includes a 6-axis industrial robot, 7th axis, vacuum gripper and generator, AI-supported optical parts inspection, conveyor belt and a safety fence with safety system.

On request, we can install the automation system, carry out CE approval and train your employees. To make it easier for you to get a quote, we have developed a configurator that allows you to configure your automation system in just two minutes.

Ejector sleeves with starting hole for flexible wire EDM

The ejector sleeves with starting hole are hardened and correspond to the basic dimensions and tolerances of the DIN ISO 8405 ejector sleeves.

The distinguishing feature is the inside diameter, which, unlike the standard, is significantly smaller over the entire length and therefore serves as a starting hole for wire EDM. This means that the required inside diameter can be quickly adapted to current requirements, for example for repairs or special dimensions.

ALL STANDARDS FROM ONE SOURCE WITH A SHORT DELIVERY TIME

ALL STANDARDS FROM ONE SOURCE WITH A SHORT DELIVERY TIME

ALL CUSTOM MANUFACTURING ACCORDING TO YOUR SPECIFICATIONS

FROM THE ON TIME DELIVERY OF THE SMALLEST QUANTITIES TO THE COMPLETE STORAGE MANAGEMENT

FROM THE ON TIME DELIVERY OF THE SMALLEST QUANTITIES TO THE COMPLETE STORAGE MANAGEMENT

WE FOCUS ON TEAM SPIRIT AND CUSTOMER ORIENTATION